| Sign In | Join Free | My wpc-board.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My wpc-board.com |

|

Brand Name : Zirnano

Model Number : B20-B505

Certification : ISO9001,ISO14001

Place of Origin : Shanxi,China

MOQ : 100kgs

Price : Negotiable

Payment Terms : L/C, MoneyGram, Western Union,paypal

Supply Ability : 3000mts per year

Delivery Time : 2-4 days after order confirmed

Packaging Details : 25kg barrel+ Pallet,2*12.5kg barrel+Carton+Pallet

Commodity : Ceramic Beads

Product Name : Zirconium Silicate Ceramic Blasting Media

Shape : Round Solid Beads

Bulk Density : 2.3g/cm3

True Gravity : 3.85g/cm3

Main Chemical : 60-66% ZrO2,25-30% SiO2,7-13% Al2O3

Hardness : 700HV Min

Size : B120: 0.063-0.125mm

Breakdown Rate 1.2% Zirconium Silicate BeadsCeramic Blasting Media JZB40 JZB60 JZB80 JZB120

1. Product of Description

Ceramic beads selects the high quality zircon sand as main material,then fused in high temperature over

2000 degrees,then screened into different microbeads according to special technology.

Ceramic beads has wide specification from B20 to B505,which can match most of the blasting equipment.

It contains 60-66% ZrO2,so it is also called as zirconium sand.It has dense crystal structure,high hardness

and low break-down rate,which can replace glass beads where one clean working condition is required.

It is one round,solid blasting media,most suitable for surface finish of metal parts due to its smooth surface

and good elasticity and high density.

Ceramic beads has lower breakdown rate,there is little dust generated in the whole blasting process,

It will ensures the worker to escape the hidden danger of silicosis. It is one clean blasting media.

2. Main Technical Data

| Commodity Name | Chemical Index | Physical Index |

| Ceramic Blasting Beads | ZrO2 60-66% SiO2 25-30% Al2O3 7-13% | Vickers Hardness ≥700 HV |

| True Specific Gravity ≥3.85 g/cm3 | ||

| Bulk Density≥2.3g/cm3 | ||

| Particle Size | B20: 0.600-0.850mm | |

| B30:0.425-0.600mm | ||

| B40:0.250-0.425mm | ||

| B60:0.150-0.300mm | ||

| B80:0.125-0.212mm | ||

| B100:0.106-0.180mm | ||

| B120:0.063-0.125mm | ||

| B150:0.000-0.125mm | ||

| B170:0.045-0.090mm | ||

| B205: 0.000-0.063mm | ||

| B400: 0.030-0.063mm | ||

| B505: 0.010-0.030mm | ||

| Special specification can be customized | ||

3. Main Features of Ceramic Beads:

No ferrous contamination to the treated parts

Low breakdown rate,no hidden danger of silicosis

Clean and bright blasting condition

More uniform and stable blasting effect

High blasting efficiency,low production cost

4. Main Applications:

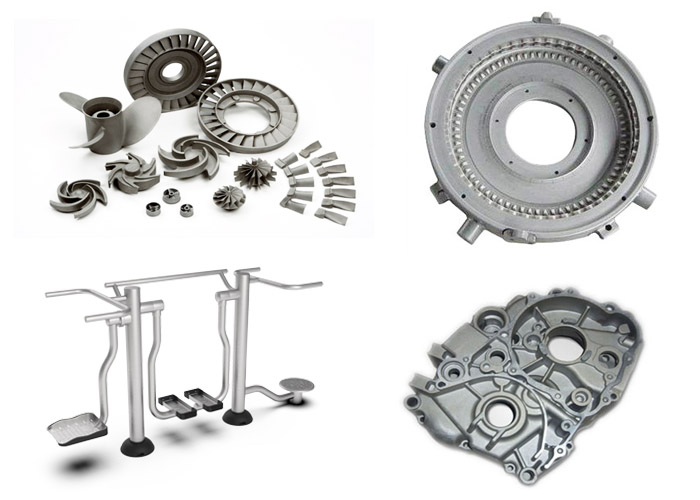

Surface finish for metal surfac,light alloys,stainless steel parts....

Surface cleaning for metal pipes,glass-bottle molds,tire-molds,die casting...

Surface cleaning for heat-treated parts,mechanical parts,electronic components...

Surface preparation for electroplating,anodizing etc.

Deburring or descaling for plastic parts,rubber parts,mechanical parts etc.

5. Main Package of Ceramic Blasting Media

25kg barrel+Pallet

2*12.5kg barrel+Carton+Pallet

Special package can be customized.

6. Why choose us?

Professional manufacturer of ceramic beads,annual output over3000mts

Professional sales and technical team,providing 7*24hrs services;

Strict quality control system,quality can be traced in every step

Double-sampling system,all the cargo will be sampled again before shipment even for one small sample

Stable supplier of Foxconn,Samsung Electonics...

Quick response and prompt delivery;

Flexible payment term,T/T,L/C,paypal is also acceptable

Free sample is available.

|

|

B120 Zirconium Silicate Ceramic Bead Blasting Media Images |